Today in beekeeping various designs of beehives are used, including rather complex ones, consisting of several buildings and tiers. However, the most common model is still the model of a single-frame frame hive. How to make such a hive for 16 frames, what are its advantages and disadvantages, as well as other secrets of keeping bees in this kind of dwelling, will be discussed below.

Bee keeping in 16-frame hives

The frame hive is a prefabricated structure, which is a box with a removable roof and removable frames in the form of a rectangle of racks with rows of wire stretched between them. Bees attach their honeycombs to it.

Did you know? The copyright for the invention of the frame hive belongs to the American Lorenzo Loren Langstrot, who patented the model in 1851. However, about forty years earlier, P.I.Prokopovich, a beekeeper from the Chernigov province, created virtually the same design, but he didn’t think about drawing up his idea.

The number of frames in it usually ranges from 8 to 24. It is this range that allows, on the one hand, to justify the cost of arranging a bee house, on the other hand, to maintain its compactness. Thus, 16 frames is exactly the “golden mean” that is optimal for a small apiary.

Advantages

- The advantages of the 16-frame hive over smaller or, conversely, larger structures are that such a model:

- quite simple and convenient to use (inspection of the framework, including for the destruction of mother liquors in order to prevent swarming, is very easy and does not require complete disassembly of the nest);

- printed without problems for pumping honey;

- provides good internal ventilation;

- quite stable and not prone to tipping over;

- thanks to the voluminous brood nest, it does not require a large number of additional extensions even during a period of large honey collection (usually two are enough), and the period during which they are not used at all is quite long;

- allows you to fully utilize all the forces of the bee family on the honey collection process throughout the summer;

- provides brood of the most egg-bearing queens;

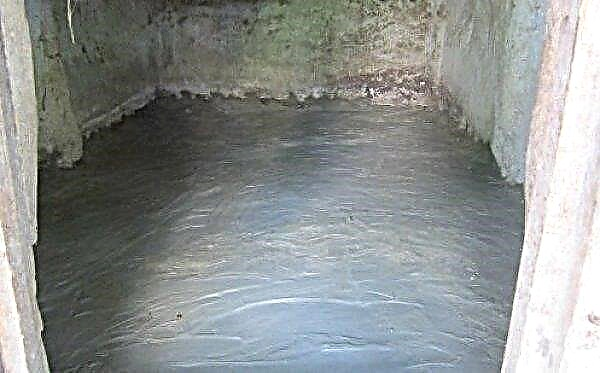

- guarantees bees a more comfortable wintering time (compared to multihull hives, where the lower case often suffers from dampness and is affected by mold) and subsequent rapid growth.

Important! A beehive with 16 frames allows you to hold a honey supply of 20-30 kg, as well as bees and pollen collected by them with a total weight of up to 5 kg.

Since the model under consideration has a number of rather significant drawbacks, which will be discussed below, some beekeepers use an upgraded design model. It differs from the usual one in that inside, the hive is divided into two cases using a vertical partition. In the first compartment leave 10 frames, in the second place the remaining 6 - 2 nesting, with mature brood, and 4 empty, with wax.

- With this design, the hive acquires several additional advantages, namely:

- gives a wide scope for choosing the configuration of the model used, depending on the specific size and strength of the bee family, current weather conditions, etc .;

- allows the allocation of additional space for the wintering of twin layering;

- allows you to easily inspect the enclosures independently of each other;

- involves a very fast and high-quality detuning of the nesting frames.

Disadvantages

- Among the important disadvantages of 16-frame hives, experienced beekeepers note:

- significant bulkiness and heavy weight (compared to models with 8 frames);

- lack of the expected more active build-up of strength by the bee family compared to the 12-frame model;

- sluggish development and poor honey collection, especially in spring;

- the tendency of bees living in such a hive to swarm (instead of exploring the empty space, the family, for unknown reasons, without gaining sufficient strength, seeks to find a new home);

- difficulty in maintenance when used to house two bee colonies.

- the most critical shortcomings of a large hive for beekeepers involved in nomadic flight of bee, because this kind of construction, especially after returning with a honey crop, is very difficult to lift alone. Problems also arise when determining apiaries for wintering.

Important! According to the observation of many beekeepers, bees master only the first dozen frames, and all the others simply ignore it. Thus, in terms of the intensity of the development of the bee colony and the volume of honey collection, the hives do not differ by 12 and 16 frames, and, therefore, the additional costs of building and maintaining a more cumbersome structure do not justify themselves.

In part, this problem can be solved by choosing the appropriate bee breed and paying serious attention to breeding work. Also, the beekeeper can be helped by using various systems for changing the internal configuration of the hive - dividing the space into two buildings, etc.

DIY hive manufacturing technology for 16 frames

By design, the frame hive consists of the following parts:

- The main body.

- The bottom, which should be removable.

- Roof (in rare cases, when hives roam in a covered van, it may not be provided).

- A ceiling in the form of a thin sheet of plywood, board or canvas (covers the upper frames).

- Frames - basic as well as spare.

- Dividing partitions (when using the two-case model).

- The diaphragm that separates families living in different buildings, or one family, from the uninhabited part of the hive.

- Store extensions (used to expand the bee colony nest).

- Insulating pillows or mattresses for wintering.

- Separation grilles to limit the access of the uterus to the extension or body.

- Arriving boards (attached to each hole from where the bees fly).

- Feeders.

In general, the model is not too complicated, and therefore, having some experience and the necessary tools, it is quite possible to make it yourself

In general, the model is not too complicated, and therefore, having some experience and the necessary tools, it is quite possible to make it yourself

Materials and Tools

The classic frame beehive is made of wood. As an alternative, which has been quite widely used over the past one and a half decades, we can name:

- plywood (as a rule, we are talking about a fiberboard - fiberboard);

- Styrofoam;

- polyurethane and other types of plastics.

When deciding on the selection of suitable material, it should be borne in mind that:

- plywood hives need additional insulation;

- foam structures are too light and unstable, therefore, they must be weighted so that they do not tip over;

- plastic with a monolithic structure does not let air through, respectively, without additional ventilation, the inhabitants of such a dwelling will die.

Thus, it is not surprising that the tree remains the option that many beekeepers prefer to any other materials for making the hive.

Important! Hard woods (oak, birch, etc.) are not suitable for the construction of hives, since they warp from moisture, poorly retain heat and crack, in addition, it is much more difficult to process them. The ideal type of wood is aspen, linden, poplar, willow, fir, spruce, cedar.

For the manufacture of a wooden hive with 16 frames you will need:

| Width of edged board (bar), mm | Consumption amount per 1 beehive, cubic meter |

| 40 - board for the front and rear walls of the housing | 0,024 |

| 30 - board for the side walls of the housing and the bottom | 0,028 |

| 25 - board for the walls of the roof | 0,012 |

| 20 - board for the end walls of the roof | 0,006 |

| 14 - diaphragm board | 0,002 |

| 50 - block for attaching the diaphragm | 0,002 |

| The list of necessary materials also includes: | From the tools you need to stock up: |

|

|

Drawings and Dimensions

A hive is best done according to generally accepted sizes. In this case, for the finished model it will be much easier to choose the internal equipment and accessories, spare frames, store extensions, etc.

In the proposed embodiment, the following sizes are used:

| Beehive detail | Sizes, cm |

| Case (internal measurements) | 61.5x45x33 |

| Folds | 2x1,1 |

| Lower letok (length) | 25 |

| Upper letok (length) | 8 |

| Arrival board (width) | 3,5 |

| Quarters on the end walls of the roof cover for the installation of shops | 1,2x1 |

| Nesting frames | 43,5x30 |

| Shop frames | 43.5x14.5 |

| Plug-in board (when using a two-case model) | 44.9x31x3.2 |

In the form of a drawing, a model of a wooden hive with 16 frames looks like this:

1 - case, 2 - socket frame, 3 - diaphragm, 4 - store, 5 - roof cover, 6 - store frame, 7 - roof, 8 - letkovy upper valve, 9 - lower valve. All dimensions are in millimeters.

1 - case, 2 - socket frame, 3 - diaphragm, 4 - store, 5 - roof cover, 6 - store frame, 7 - roof, 8 - letkovy upper valve, 9 - lower valve. All dimensions are in millimeters.

Hive equipment inside

The proposed version of the 16-frame hive is a sunbed, suggesting the location of the bee nest in a horizontal plane. Nest frames in this hive are located in the central part, and honey frames are closer to the edges. When equipping the nesting and store departments, special dividing frames are provided. This allows the beekeeper to get more space for examining the inside of the hive and pumping out honey.

In order to fasten the frames in the inner part of the store, folds with a section of 1.1x2 cm are made on the front and back walls. This procedure is performed after assembling the bottom and the nesting compartment with letches.

Did you know? The ancient Egyptians believed that after the death of a person his soul flies out of the body in the form of a bee. This insect was also revered no less in antiquity: the Greeks often depicted as a bee one of the most revered goddesses - Artemis, who patronizes hunting, is responsible for fertility and symbolizes female chastity.

In the upper part of the shield, on the outside of each wall of the case, quarters of wooden boards are built in, on which store extensions will subsequently be installed. The outer part of the quarter is used to install the roof liner. It is installed in the upper part of the hive and fixed with nails.

The diaphragm, which is a frame of boards with a thickness of 14 mm, is attached to the body with a bar and then tightly pressed against the inner walls and the bottom using a rubber sheet.

It is important to provide ventilation holes during the assembly process.. They are performed on the sides of the roof, in its end walls. Letters, which open the way for the bees out, are cut on the front wall of the body. Finally, the shield, which is the bottom of the hive, is fixed with nails to the walls so that its lower part protrudes outward and acts as an arrival area. A protective net should be installed under the shield.

Video: Assembly diagram of a 16-frame hive

Bee keeping technology in 16-frame hives

The beehive lounger for 16 frames in the classic version is designed for growing one bee family. The content of winged toilers in such a model is a fairly simple process when compared with other varieties of hives.

Due to the absence of problems with damping of the structure during the wintering period, in spring, bees can stay in the same dwellingthey don’t need a transplant.

After the insects made their first test spring flight, the beekeeper should nevertheless carefully examine the contents of the hive and assess the condition of the family. In the course of such an audit, the death of the bee is removed from under the framework (to make it more convenient to do this, in the autumn you can lay out the bottom of the hive with a film where dead individuals will fall off).

Checking the condition of the hive after wintering, food stocks should also be inspected. If all the food left for the winter has been eaten by insects, honey must be added to the hive before replenishment of the hive and honey, and the contaminated and empty frames should be removed. Only those frames that are currently used by insects should remain inside.

After the audit, the frames are covered with burlap and a mattress, tightly pressing its edges to the roof cover and walls. Now the bees can not be disturbed for 2-3 weeks.

When the period of active flowering of the first honey plants begins, the number of frames should be increased by 4–5 pieces, placing them close to the brood frame. In the future, as the bee family grows, the hive is filled completely with wax frames.

After all the frames are filled, the beekeeper needs to proceed to the formation of layering, dividing the family by half a year. Rebuilt, but not ripened queen cells should be destroyed to avoid swarming. Mature mother mothers leave, otherwise swarming cannot be avoided, it just happens later. But store extensions in this situation are not put in the hive.

Did you know? Archaeologists have proven that the history of bees dates back to at least 30 million years (during excavations dating back to the Tertiary period, petrified remains of these insects were discovered). It is noteworthy that man appeared on Earth only 2 million years ago, and intelligent man is even smaller.

The selection and pumping of honey begins after the bees begin to seal the honeycombs in store extensions.

In the steppe regions, where bees do not usually collect a pad, the honey frames leave the insects for wintering, placing them on the sides of the hive opposite the brood frames. In forest areas, it is better to replace part of honey as winter food with sugar syrup.

After the honey collection is complete, the hives are cleaned for the winter in special rooms, where a constant temperature should be maintained in the range + 1 ... + 3 ºС

After the honey collection is complete, the hives are cleaned for the winter in special rooms, where a constant temperature should be maintained in the range + 1 ... + 3 ºС

Tips from experienced beekeepers

Beekeeping is a very ancient craft, and for many centuries during which mankind has mastered its technology, considerable experience has been accumulated. In order to avoid offensive mistakes and turn the content of the apiary not only into an exciting activity, but also into a profitable business, It is worth using the following important recommendations:

- Never do not place the hive directly on the ground. To do this, it is imperative to provide a stand made of wood, metal, polymer materials, or at least a brick.

- An apiary should not be placed in an open area, because although the bees can tolerate extreme heat, they use their own wings as a hundred small fans to cool. Thus, instead of collecting pollen and making honey, the "residents" of the hive will be engaged in an absolutely useless business from an economic point of view. therefore for hives it is important to choose a shaded place where the temperature during the day does not exceed + 28 ° C (inside the house it will be about 6 degrees warmer, but such a microclimate for bees is quite comfortable).

- In addition to protection from the hot rays of the sun, bees need silence for good performanceTherefore, a place for an apiary must be chosen away from sources of loud noise.

- When using the nomadic beekeeping method it is advisable to exhibit an apiary in the same parking lot every year. This will allow smart bees with a good memory to not waste time exploring a new territory, and it is also easier to find the return path to the hive.

- Untimely pumping out of honey is a mistakeleading to large losses in productivity (sometimes by half).

- The front walls of the hives are desirable paint in different colors, this simple trick allows bees to easily recognize their home and not fly into someone else’s (in the latter case, the “lost” insect often becomes a victim of fellow tribesmen guarding the entrance).

- Beehives are best placed so that letki “looked” to the north. This orientation to the cardinal points, on the one hand, allows you to warm up the back wall, on the other hand, provides maximum ventilation.

- When organizing an apiary, you should always ensure that there were no residential buildings, playgrounds or other objects for people, children and pets between the hive and the honey plants.

- If you foresee structural insulation already in the process of manufacturing the hive, you can save a lot on the winter house by leaving the bees in the cold season right in the apiary.

- When making or acquiring a hive, you need to immediately worry about reserve frames and spare stores.

- The right bee breed - An important condition for a successful business. Insects differ from each other not only by immunity and fertility, but also by adaptation to different climatic conditions and nature. A novice beekeeper should pay attention to those breeds that are considered the most calm and least aggressive.

- Bees do not get used to their master and are not able to recognize him. The absence of painful bites is primarily the result of careful attention to your work and maintaining constant control over the situation. In addition, when planning to create an apiary, you need to advance stock up on a full set of protective clothing.

A 16-hectare frame beehive is a very common design that has both a number of obvious advantages and some significant drawbacks. Choosing this model, the beekeeper should carefully weigh all the "pro" and "contra", as well as carefully consider the size of the future apiary, the place of its installation, method of use (stationary or mobile), climatic conditions and many other details associated with the planned breeding of bees. No less important is a detailed study of the drawings and the internal arrangement of the hive, although if all these conditions are met, it is not at all difficult to make such a structure and successfully use it.