If you properly prepare wheat moonshine at home, it will have not only a mild taste, but also have a pleasant grain and bread flavor. Many experts say that it is precisely due to their taste properties that this product is so popular among the population of Russia. An important stage in the preparation of a drink is the preliminary germination of grain. And this process should be given special attention.

Why germinate wheat for moonshine

In order to understand why to germinate wheat for the manufacture of home-made moonshine, you should understand the essence of this process.

The creation of any alcoholic product is based on the main biological process - fermentation. Unicellular yeast fungi take part in it. They feed on carbohydrates, and in return give ethyl alcohol. By-products of their livelihoods are also carbon dioxide and some heat.

In the production of home-made moonshine from wheat, it is grains that are the source of nutrition for these microorganisms. Only this product contains a huge amount of carbohydrates.

In the production of home-made moonshine from wheat, it is grains that are the source of nutrition for these microorganisms. Only this product contains a huge amount of carbohydrates.

Nevertheless, there is also a little complexity. It consists in the fact that the carbohydrates in this crop are represented by starch polysaccharide. It is these molecules that yeast cannot eat directly. Only when a germ appears in the grains does the process of enzyme release begin. They break down all starch into simple carbohydrates - fructose and glucose.

Many specialists in moonshining argue that an important step in wheat germination is the exact determination of the time when starch began to turn into simple carbohydrates. It is important not to miss this moment. Otherwise, substances useful for a strong drink begin to be consumed, allowing the sprout to grow in size. That is why it is important to comply with the deadlines indicated in the recipes and strictly follow them.

Did you know? Moonshine has long been used to treat colds. But they recommend drinking no more than 50 g per day during the period of illness.

The seed that has sprouted is called green malt. This product requires immediate use, as it is practically not stored. If it is necessary to create its annual supply, then the products are dried.

Video: Green malt with your own hands

Germination of wheat for mash

Braga is the most important component for making this strong drink.

The main goal of the moonshiner is to maximally competently and efficiently reproduce the conditions for the germination of grain in the ground. Therefore, you should carefully monitor several parameters at once:

- humidity

- lack of direct sunlight;

- ambient temperature.

An excellent indicator will be the absence at the time of germination of the temperature above + 18 ° C. If this figure is further reduced, then the yeast mushrooms will begin to develop less actively. This reduces the likelihood of spoiling a quality product to a minimum.

Wheat Selection Rules

The main characteristic of wheat suitable for creating moonshine is its viability. This will allow the grains to germinate simultaneously and in the shortest possible time. In this process, in almost 100% of cases, a healthy germ is formed.

There are a number of strict rules for choosing it:

- On sale wheat grains that are intended for sowing should be chosen. Feed or feed cereal, after assembly, undergoes a heat treatment process. This technology allows not only to preserve the seed material longer, but also to disinfect it from various diseases and microorganisms. Accordingly, feed wheat has a non-viable sprout. It will not be possible to germinate it under any conditions.

- Particular attention should be paid to grain size.. If it is too small, then most likely this crop was harvested in advance. Expect good similarity from him is not worth it.

- Should refuse to purchase wheat in which there are other impurities. It can be weed seeds, dirt, dust, crushed grains. If such a product is offered, then, most likely, the seller is trying to sell fodder planting material.

- The appearance of wheat plays an important role. Its surface should always remain smooth and even. Her color should be uniform. If there are wrinkles or spots on the grain, this indicates a low quality product.

- If the wheat sold is of the highest class, then a dense and uniform structure should appear on the grain break. If the product is feed, then inside you can often find air pockets. It is thanks to these cavities that the grain floats to the surface of the water during washing.

- It should be understood that the grain just past the stage of threshing has not yet matured. Therefore, it is not able to germinate. After harvesting, wheat should be stored for at least 2 months. And only after this period it can be turned into an excellent product for brewing moonshine. It is also worth remembering that if the grain is stored for more than 2 years, the probability of germination is extremely low.

Every experienced brewer knows that choosing the right material is not easy. Therefore, people often turn to seed stores for quality wheat. You can also search for suitable products in the markets. Particularly actively begin to trade in good wheat before sowing.

Every experienced brewer knows that choosing the right material is not easy. Therefore, people often turn to seed stores for quality wheat. You can also search for suitable products in the markets. Particularly actively begin to trade in good wheat before sowing.

Preparatory work

On any acquired wheat, there are a large number of microelements unfavorable for the subsequent process of making mash. It can be various bacteria, mold fungi and ordinary dust. If they enter the nutrient medium, then they begin to compete with yeast fungi. In this case, there is a process of absorption of carbohydrates, but the absence of ethyl alcohol at the outlet.

To avoid such a fate, the moonshiner must carry out a whole range of preparatory work, namely:

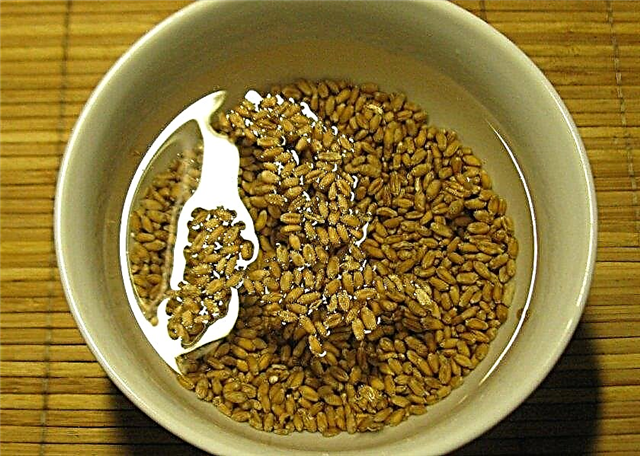

- All wheat is placed in a specially prepared deep container. Water of room temperature is added to it. At the same time, dishes made of stainless steel should be discarded. It is better to use glass, plastic or ceramic products.

- Grains are thoroughly mixed. Surfaced husks, low-quality seeds, dirt, dust and weed residues are removed from the surface.

- Then the water is drained. This procedure is carried out until the water is completely clean. The fluid from the last wash must also be drained.

- Next, a solution of potassium permanganate is prepared using 2 g of the substance per 10 l of water. This composition is placed in the same bowl where the washed wheat grains remain. In this form, they undergo disinfection for 3 hours. It is believed that this amount of time is enough to completely remove bacteria and malignant microorganisms.

- Then the potassium permanganate is drained, and the products are washed several times in water at room temperature.

- Now you can pour wheat with clean water so that the liquid level exceeds the number of grains by 2-3 cm. It is necessary to use exceptionally soft water, since hard water inhibits the germination process and can increase the likelihood of souring. You can not use boiled liquid, since it lacks the oxygen necessary for the flow of biological processes. If water is taken from a common pipeline, then it should be defended for a day before use or filtered in special equipment.

- In this state, wheat is left in a place without sunlight for 6-8 hours. The temperature here should remain within +14 ... + 16 ° С. As soon as the time allotted for this process expires, the water is drained. Grains are left for another 6-8 hours in a well-ventilated place without light to dry.

- Such six to eight hour soaking and drying cycles are repeated twice more. This technology will allow wheat to be saturated with moisture before germination, but will not let it sour.

The main condition for this process is compliance with temporary standards. If the grains lie in the water longer, the process of returning carbohydrates will begin. And this negatively affects the future product. If the last batch of water is filled with starch, then the wheat gave part of the sugar. This means that the moment is lost.

The main condition for this process is compliance with temporary standards. If the grains lie in the water longer, the process of returning carbohydrates will begin. And this negatively affects the future product. If the last batch of water is filled with starch, then the wheat gave part of the sugar. This means that the moment is lost.

Germination process

Wheat is the only cereal for moonshine that grows slowly. Such a leisurely process can lead to the formation of unnecessary secondary microorganisms. They significantly worsen the future wort. Therefore, it is necessary to strictly observe the time frame and adhere to the recommended temperature indicators.

Did you know? Most Russians are convinced that moonshine is their folk drink. But, similar alcohol is found in Ukraine, Hungary and even Ireland.

The whole process of germination is divided into several important steps:

- Prepared wheat grains are laid out in a uniform layer on any suitable metal surface. For this you can use any pan. The thickness should be 3-5 cm. If it is possible to use lattice products, then they will ensure the outflow of excess fluid.

- A clean cotton cloth is placed on the surface of the pan in such a way that it covers the entire surface of the grains. Such a wrapping will allow to avoid not only drying out, but also minimizes the likelihood of acidification of the malt. Matter absorbs residual moisture and, with the probability of grain drying out, gives it to wheat.

- In this form, the metal pan must be placed in a well-ventilated dark room, maintaining the temperature within +14 ... + 16 ° С. It is necessary to minimize the chance of direct sunlight on the material being prepared. Therefore, if light enters the room, it is recommended to close the curtains.

- About 3-4 times a day should be carefully so as not to damage the sprouts, mix the wheat. The most suitable appliances for this purpose are a construction spatula or a wooden spatula for cooking.

- During this process, the germinated product should be checked for moisture by touch. If necessary, they should be irrigated with spray water.

- If the procedure is performed correctly, on the second or third day, tiny white sprouts will begin to appear. In the natural environment, they would become the rhizome and the aerial part of the plant.

In addition to germinating grains, it is important to timely identify the readiness of the malt. If you stop this process earlier, then the starch will not have time to completely transform. This will increase the time at the time of fermentation. When wheat germination is completed too late, there is a chance of complete absorption of carbohydrates.

Important! If untimely notice the readiness of the malt, a delay of only a few days can lead to a significant deterioration in the quality of the finished product.

Therefore, many experienced moonshiners have learned to determine important criteria for the optimal state of sprouted grains:

- the length of the sprouts does not exceed 1.5 cm;

- the aroma coming from the pan should resemble the smell of freshly picked cucumbers from the garden;

- the sprouts of adjacent seeds begin to weave, forming tangled shoots.

At this step, the germination process ends. The collected material is suitable for addition to the wort for a maximum of 4 days.

At this step, the germination process ends. The collected material is suitable for addition to the wort for a maximum of 4 days.

What to do if it does not germinate

Quite often, inexperienced moonshiners report that wheat has not sprouted for the above time. This situation may occur for several reasons.

Firstly, poor quality wheat, as reported above, can cause the lack of sprouts. Therefore, you should choose the right grains for this process. SecondlyPoor preparation work may damage the product. Only clear and competent observance of the rules described in the paragraph “Preparatory work” will help to avoid such a situation.

If the germination process was performed correctly, then the probability of the absence of sprouts is minimal. If during the next 2-3 days after the end of the terms indicated in the technology, wheat did not germinate, then it can be safely thrown away. This strong drink is not recommended to be prepared from it.

How to Get Wort from Sprouted Wheat

To get wort from sprouted wheat, you will need to go through several main procedures. Among them:

- boiling;

- saccharification;

- cooling;

- yeast application.

Each of these processes will require strict adherence to generally accepted rules and regulations.

Boiling

The digestion procedure proceeds under the influence of steam. Open fire can cause burning of wheat, which is unacceptable in the manufacture of moonshine. To implement this process, you will need special equipment - a steam generator and a container for the wort.

Sprouted wheat grain is poured with hot water. Its temperature should be approximately + 50 ° C. In this case, the mixture is thoroughly kneaded, preventing the formation of lumps. For every kilogram of raw material, 4 l of liquid is added. Further, the temperature gradually rises to +55 ... + 60 ° С. It is fixed for 15 minutes. During this time, the secreted enzymes begin to interact.

Then turn on the steam generator at full power. The wort temperature is again increased by 5 ° C and fixed for 15 minutes. Then you need to mix the mixture every 10 minutes and bring it to a boil. Cooking lasts approximately 1.5–2 hours. The worse the raw materials, the longer this process will last.

As a container, you can use any dishes made of ceramics, glass or metal that cannot transfer the catalysts of the prepared mixture.

As a container, you can use any dishes made of ceramics, glass or metal that cannot transfer the catalysts of the prepared mixture.

Saccharification

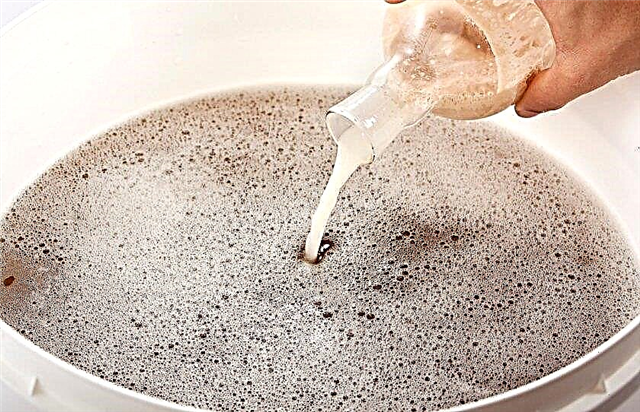

The resulting wort is subject to a cooling procedure. It is advisable to do it quickly. Lower the temperature to + 65 ° C. At this time, add malt milk. Now the mixture is thoroughly kneaded.

Important! It is better to avoid acquiring a large batch of grain immediately. You can take a certain amount and see how it will germinate.

The container with this mixture must be wrapped, keeping warm, and stir constantly every 30 minutes. In 1,5–2 hours the process of saccharification will be completed. An important point is maintaining a constant temperature. It is undesirable to lower or raise it.

After the specified time, you need to taste the mixture. If she acquired a characteristic sweet flavor, then the process can be considered successfully completed.

After the specified time, you need to taste the mixture. If she acquired a characteristic sweet flavor, then the process can be considered successfully completed.

Cooling

The resulting mixture is to be cooled for the subsequent fermentation process. The procedure should be carried out quickly. The temperature should drop sharply to +28 ... + 30 ° С. The ideal option in this case is a curved copper tube. It is placed in a container. One end is connected to cold water, the other is taken to the drain.

Yeast infusion

The final step in the wort production process is the step of introducing yeast. During this procedure, it is important to maintain the temperature within +28 ... + 30 ° С. If you lower the performance, fermentation will be slower. In some cases, the process stops altogether. This leads to a decrease in the amount of alcohol in the outlet. An increase of at least 1 ° C increases the formation of wild yeast (they reduce the amount of alcohol in the finished product) by 2 times.

The ability to properly sprout wheat is considered one of the most important in the entire process of home brewing.However, without knowing the technology and recipes, to get quality products also will not work. Therefore, experienced moonshiners often look for secrets of this matter in various media. You can get recommendations from old records of grandfathers and great-grandfathers. To make home-made moonshine of high quality, it is recommended to consult with more experienced colleagues.